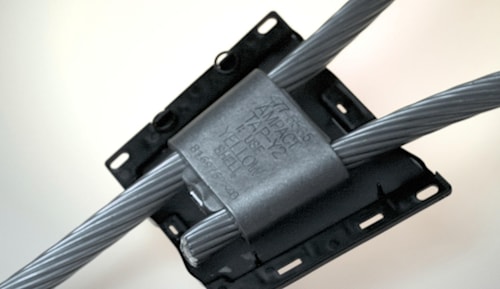

TYCO ELECTRONICS CANADA ULC 600456 C-Tap Connector Medium, Insulated, Wedge 4/0-4 AWG

Description

Tap connectors use the action of a metal wedge to secure the two conductors to be connected at opposing ends of the C-clamp. The wedge is inserted at a speed of about 40 m/s using the AMPACT connector tool. High-speed insertion is very effective in abrading all sliding surfaces and in disrupting surface oxide film to generate large numbers of contact spots in the electrical interfaces. The C–member remains attached through the residual elastic force developed in the clamp. This force is sufficiently large to maintain a low electrical contact resistance but is insufficient to cause conductor plastic flow and ensuring stress relaxation in the connector. The elastic force also helps prevent creepage by compensating for expansion and contraction of the assembly during thermal cycling. The presence of an inhibitor in the electrical interfaces protects electrical contact spots from corrosive attack during use.

Specifications

| Brand Name | TE Connectivity | Item Name | C-Tap Connector |

| Type | Medium, Insulated, Wedge | Voltage Rating | 0 - 500 kV |

| Tap Conductor Size | 4/0-4 AWG | Color Code | Blue |

| Material | Aluminum | Width | 2.6 in |

| Height | 1.62 in | Temperature Rating | -40 to 150 °F |

| Standards | EU RoHS Directive with Phthalates Amendment 2011/65/EU, 2015/863/EU, RUS Approved, RoHS Compliant | Application | For Overhead Transmission and Distribution Connections |